Product Introduction

- What is Platinum Colloid?

-

From Platinum to Platinum Colloid:

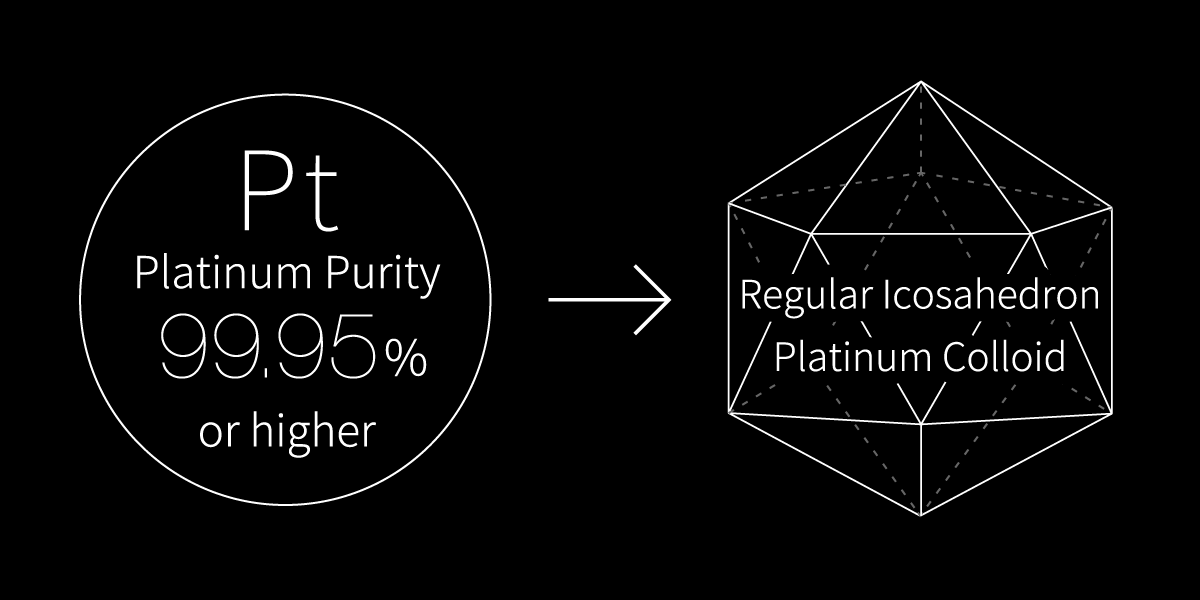

Platinum (Pt), a mineral, is found in about 3 grams per ton of platinum group ore. This rare platinum is refined to a purity of over 99.95% to become the raw material for platinum colloid.

Platinum is a very stable metal (solid), resistant to heat and acids, but it can be dissolved (ionized) by a strong acid called aqua regia. Inovex's platinum colloid is made by reducing platinum, which has been ionized, in water and stabilizing it again as metallic (solid) platinum particles, resulting in a colloidal state (where platinum particles are dispersed in water).

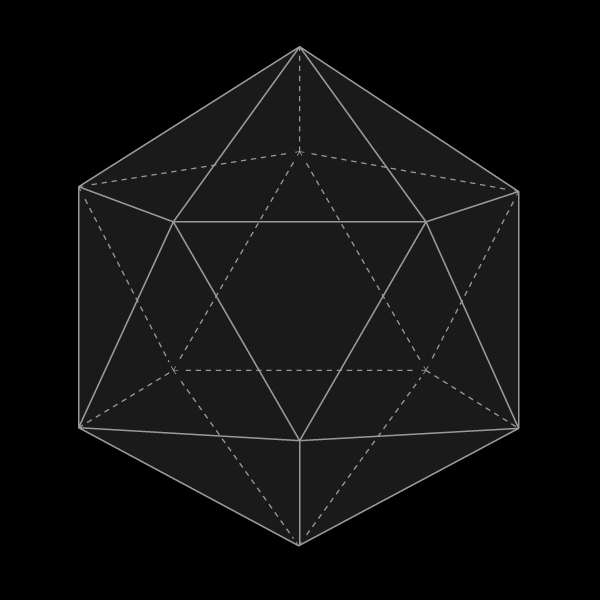

In the manufacturing process of platinum colloid, platinum ions are heated and stirred in water for a long time, forming a single aggregate of platinum atoms with a regular icosahedral structure. This serves as the nucleus, and more regular icosahedral platinum particles are produced sequentially, with all ionized platinum reduced to platinum particles, completing the platinum colloid.

The aggregate of platinum atoms forming the regular icosahedral shape is considered to contain 147 or 309 atoms, with 92 atoms appearing on the surface in the case of 147 atoms, and 162 in the case of 309 atoms. This results in a vast surface area and an electron cloud surrounding the particles, maintaining a zeta potential of (-) 40mV, exhibiting high antioxidant capacity and continuous electron donating ability.

The safety of platinum colloid has been proven through over 25 years of research and practical use, but the elucidation of new functions, such as the emission of photons in the visible light range and the generation of sound in the audible range, is still awaited.

- Platinum Beverage "sai®"

-

Platinum Beverage "sai®"

Since obtaining the world's first manufacturing permission for a platinum beverage in September 2000, Platinum Beverage "sai®" has been consumed by over 370,000 people for more than 20 years. In an increasingly complex stress society, the role of "sai®" is significant, attracting attention not only in Japan but also overseas.

Manufactured using a unique metal salt reduction reaction method and ultrafiltration manufacturing method.

<Regular Icosahedral Molecular Structure>

It has been confirmed through electron microscope photography by universities that the platinum contained in "sai®" has a regular icosahedral structure for each particle. Additionally, it has been proven that the regular icosahedral structure is composed solely of platinum atoms.

<Maintaining Potential>

The properties of the platinum nanoparticles in "sai®" were observed with a transmission electron microscope (TEM), revealing that the regular icosahedral particles are uniformly dispersed in water. The electrical properties of the platinum nanoparticles' surface, measured by zeta potential methods, showed a negative (-) 40mV. This confirms that the platinum nanoparticles in "sai®" maintain a negative surface charge, unlike platinum used in other platinum products, thus making it a colloid with electrical properties.

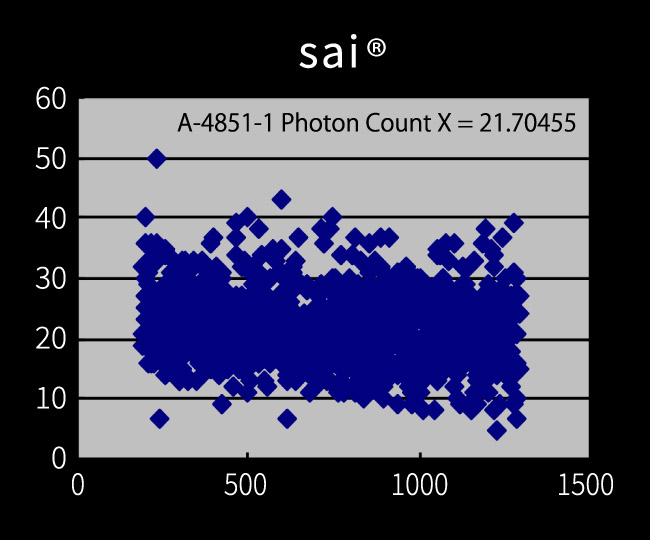

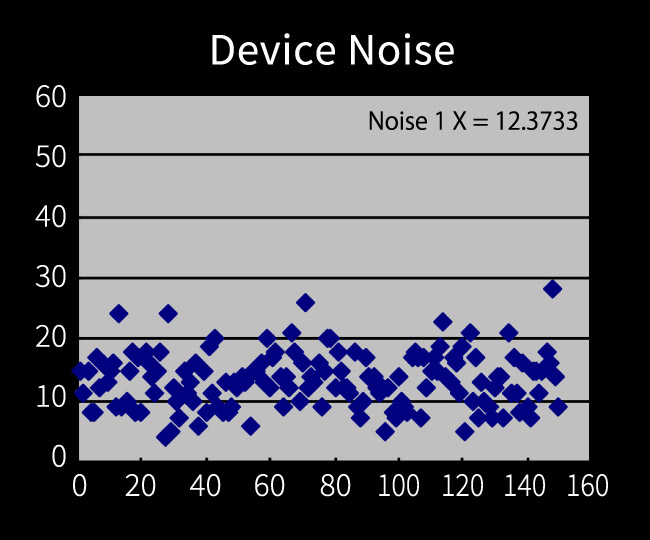

<Water Emitting Light>

In 2005, measurements using a weak photon counting device manufactured by Hamamatsu Photonics showed that "sai®" emits 9 photons (particles of light) per second in the visible light range. It is believed that platinum particles emit photons and glow due to interactions involving the electron cloud covering the particles.

- vuvu®500・vuvu®2000

-

Platinum Colloid "vuvu®500" & "vuvu®2000"

"vuvu®500" and "vuvu®2000" were developed in 1999 using a unique metal colloid manufacturing method for the purpose of cosmetic raw materials and were patented as "cosmetics containing platinum colloid" (former name: "cosmetics"). Additionally, the platinum colloid for cosmetic raw materials was registered with INCI in 2002, pioneering globally, and has been utilized by over 500 cosmetic manufacturers domestically and internationally.

-

- Antioxidant power due to the electrical properties of the platinum surface.

- Continuous reducing power due to the negative potential of the platinum surface.

Four Functions [Data on vuvu®]

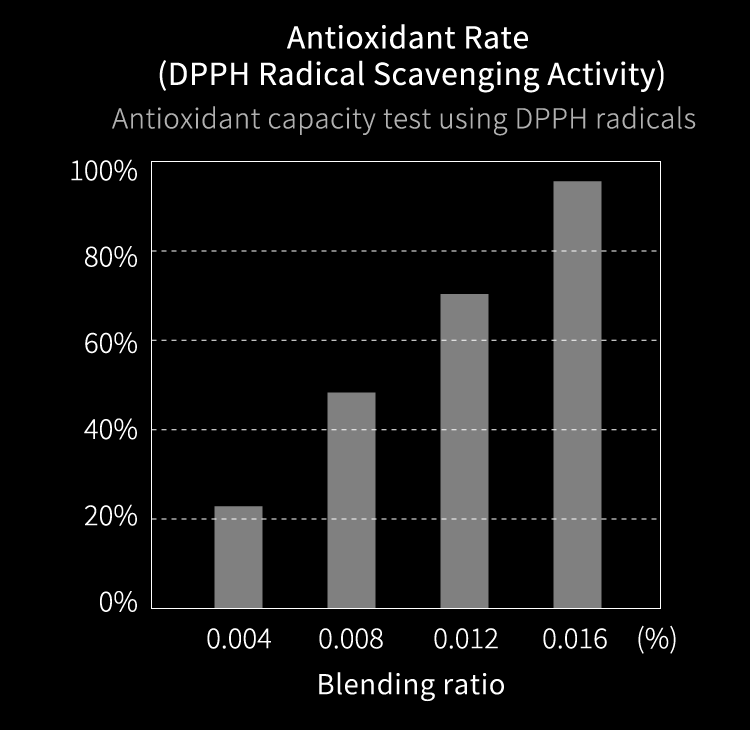

Proof of Antioxidant Power

The antioxidant power increases in proportion to the blending ratio.

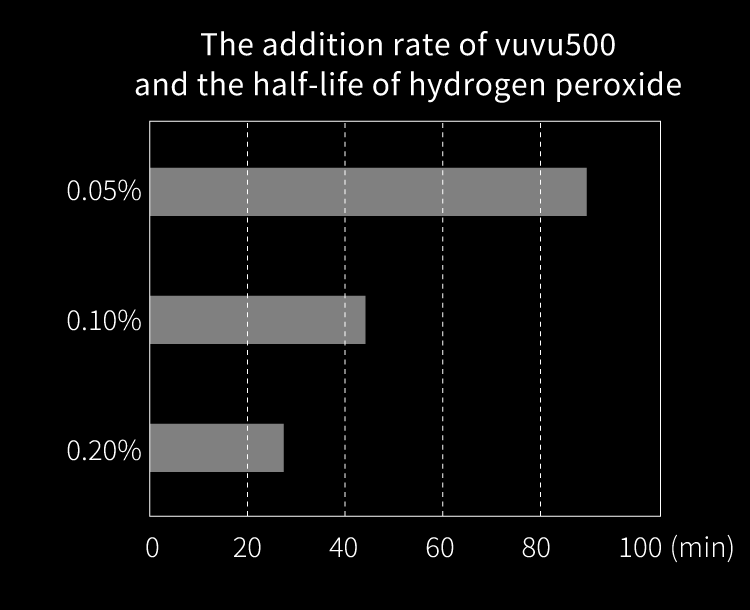

Elimination of Reactive Oxygen Species (Hydrogen Peroxide)

Reactive oxygen species are eliminated in proportion to the blending ratio.

Proof of Safety

-

- Seven safety data items obtained:

Acute oral toxicity / Primary skin irritation / Continuous skin irritation Sensitization / Eye irritation / Mutagenicity / Human patch

No UV absorption. - Does not permeate the skin. *2

- Does not remain in the body after oral administration. *2

- 28-day repeated dose testing completed.

- Not absorbed by the body when consumed. *3

- Seven safety data items obtained:

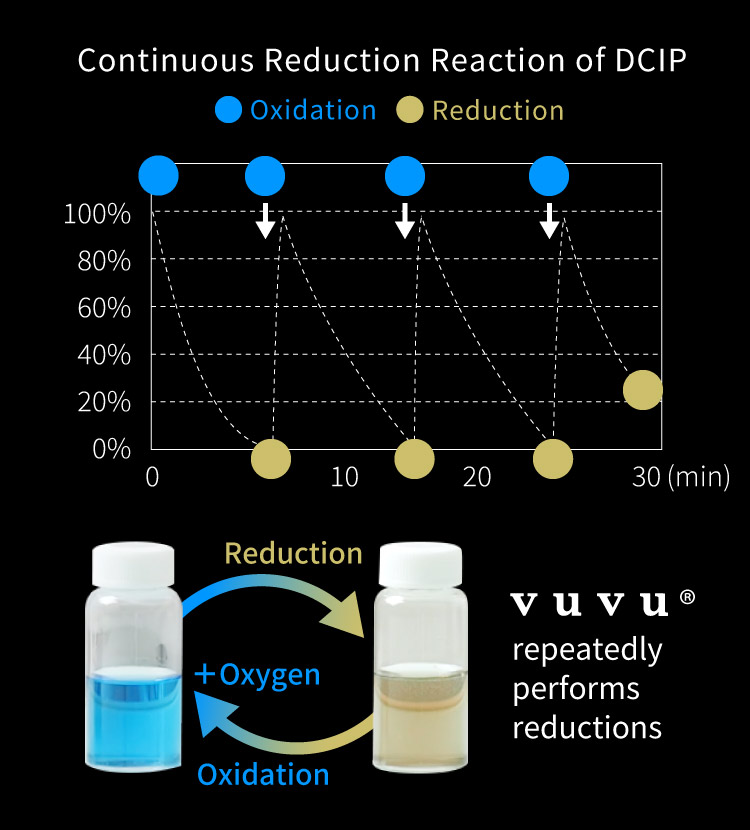

Demonstration of Continuous Reducing Activity

In experiments using blue oxidized dye (DCIP), continuous reducing power was demonstrated even after re-oxidation.

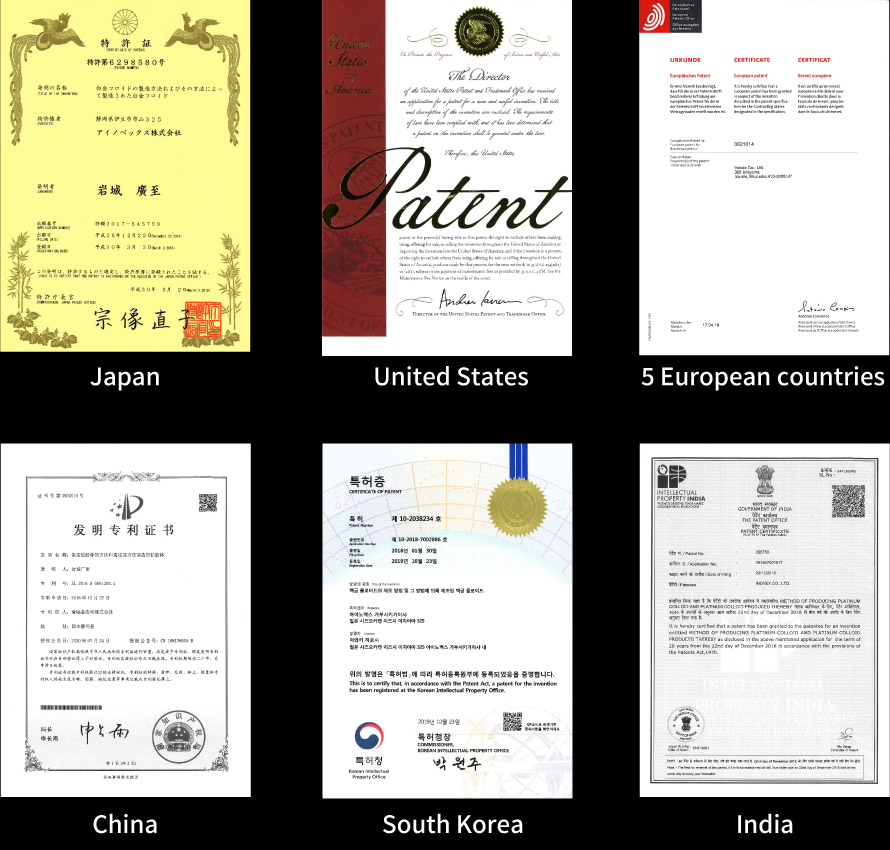

- Patent Acquisition Status

-

Patent Acquisition Status

<Manufacturing Method Patents>

Countries with Patent Acquisition: Japan, USA, UK, France, Germany, Switzerland, Turkey, China, South Korea, India INOVEX Corporation

INOVEX Corporation

(As of April 2024) - Safety Information

-

Safety Test Results

Safety of INOVEX Platinum Colloid

Introduction

There are two methods to produce fine metal particles: the top-down method, which involves crushing a metal mass into fine powder, and the bottom-up method, which generates metal particles from gases or solutions. Due to the very fine nature of platinum particles, they are mostly produced using the bottom-up method. Additionally, nanoparticle production in the gas phase is called the gas phase method, while production in a liquid medium is known as the solution method. For platinum colloid, the solution method is primarily used.

Platinum Colloid Manufacturing Method

Common methods for manufacturing platinum colloid include reducing platinum salt dissolved in a solution to generate platinum particles or irradiating a platinum plate in a solution with laser light to produce platinum particles. However, differences in particle generation conditions, materials used to protect particles, types of solvents, and purification methods can result in platinum particles of similar sizes having completely different properties and uses. Industrial platinum colloid requires uniform particle size, good dispersion, and suitable solvents. In contrast, platinum colloid used in food and cosmetics prioritizes safety and stability, necessitating product compliance with respective standards and regulations. Recently, platinum colloid has been increasingly incorporated into many cosmetics and foods as an antioxidant. However, the efficacy of these products varies greatly depending on the manufacturer and production method, with some products exhibiting little to no antioxidant activity. Additionally, even if the stability of platinum particles is maintained, there are concerns about the absorption of platinum particles through the skin or digestive tract into the body, and manufacturing methods leaving low molecular weight ion substances in the colloid do not guarantee safety.

Our Unique Manufacturing Patent

Our manufacturing method for food-grade platinum colloid strictly selects base agents recognized for food use, while for cosmetic-grade platinum colloid, base agents recognized for cosmetic raw materials are selected. To ensure the safety and stability of the platinum colloid in the final manufacturing stage, we use an ultrafiltration membrane with a fractionated molecular weight size of 30,000 to remove ion substances that have passed through the membrane. This ultrafiltration process is made possible by the carefully selected base agents and our unique patented manufacturing method (patented in 10 countries worldwide), guaranteeing the superior safety and stability of Inovex platinum colloid.

Regarding Safety

Since the start of platinum colloid manufacturing in 1996, we have prioritized safety, and no results indicating toxicity, hazards, or absorption into the body through the skin or digestive tract have been observed in various scientific tests. For food-grade platinum colloid, in 2000, we submitted data on physical and chemical properties and safety to the approval authority and received manufacturing approval as a food additive "platinum" and permission for the production of soft drinks. Additionally, we have passed various safety tests and have over 20 years of drinking history as a soft drink. For cosmetic-grade platinum colloid, it was the first raw material using platinum to be registered with INCI (International Nomenclature of Cosmetic Ingredients) in 2002. After conducting various safety tests, it has been used by many cosmetic manufacturers both domestically and internationally since 2002 and is incorporated into numerous products, including skincare, hair care, and makeup products.